Our Process

Herreen is reshaping the way Custom MGF Footwear and Orthotics are designed, ordered and manufactured.

It is where craftsmanship meets innovation resulting in easy-to-use technologies to produce cost-effective functional products.

Are you a Healthcare Professional or Carer wanting ‘normal’ looking footwear at an honest price?

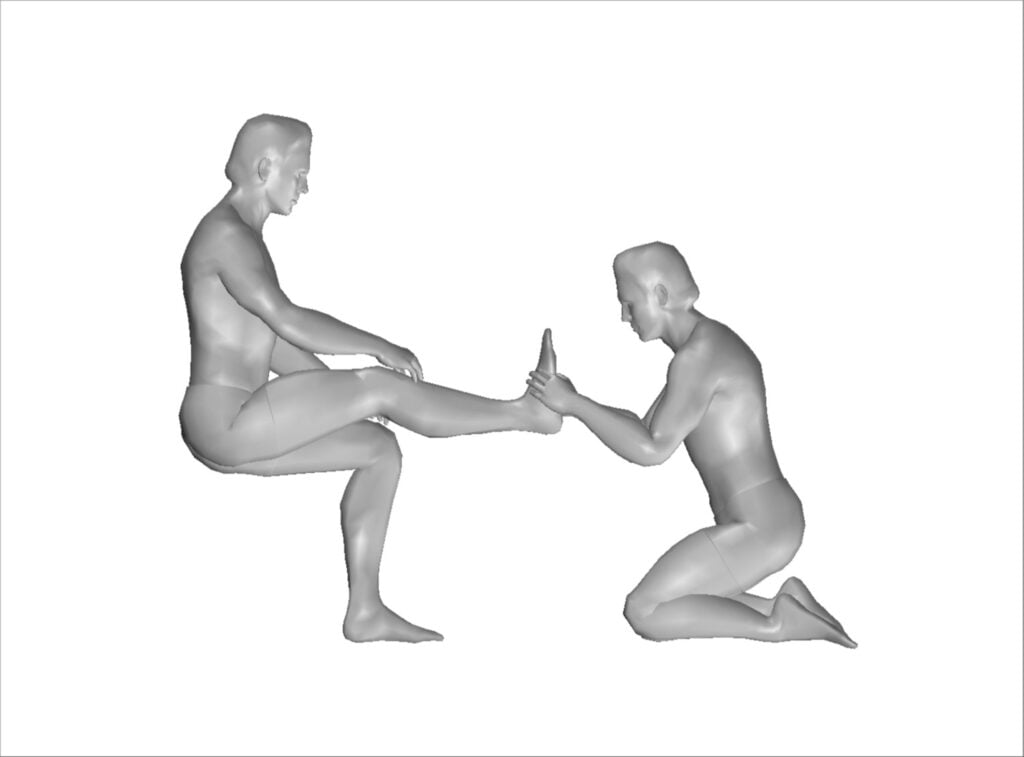

Step #1

A manual assessment of the feet is done to confirm foot type and future requirements of the footwear and orthotics.

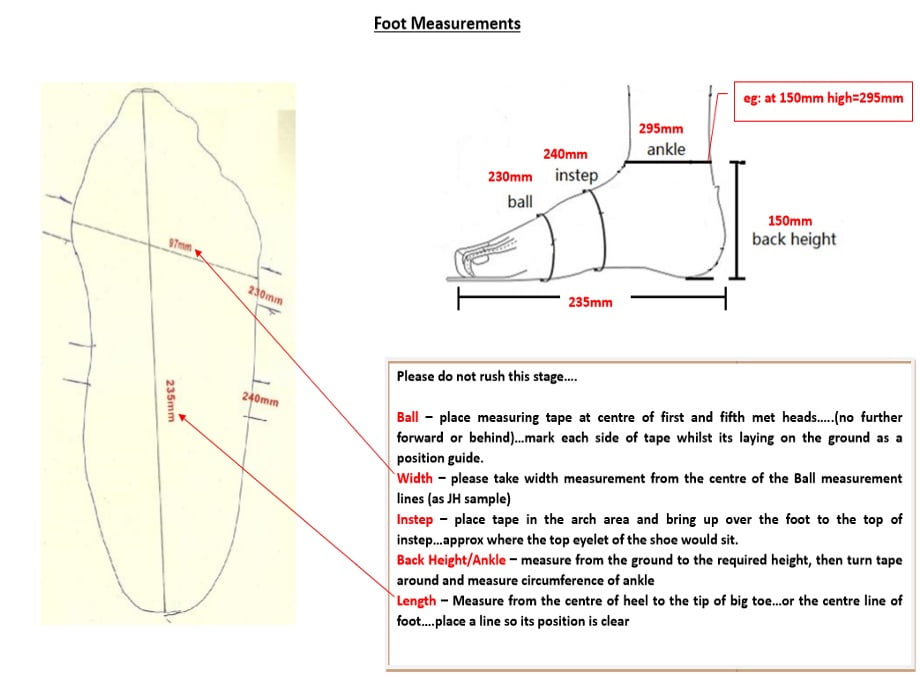

Step #2

Even though we take a 3D scan to capture foot shape and contours it is important to take a tracing-measurement to help with future designs.

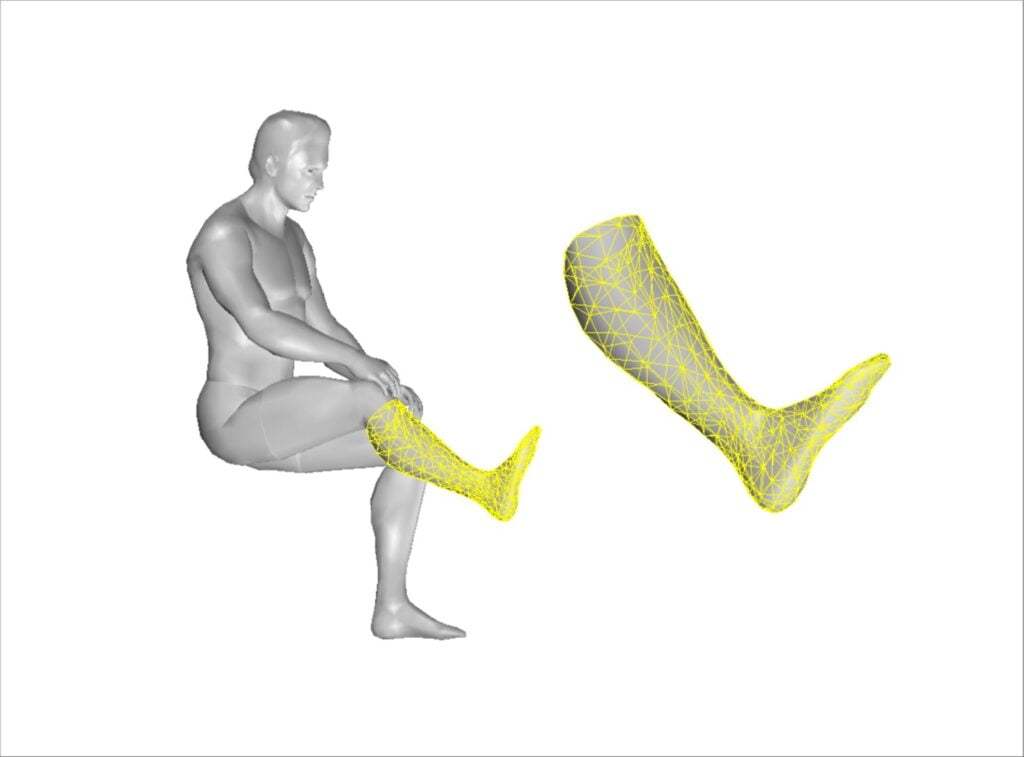

Step #3

A 3D foot scan captures the foot, ankle and lower leg in less than 1 minute.

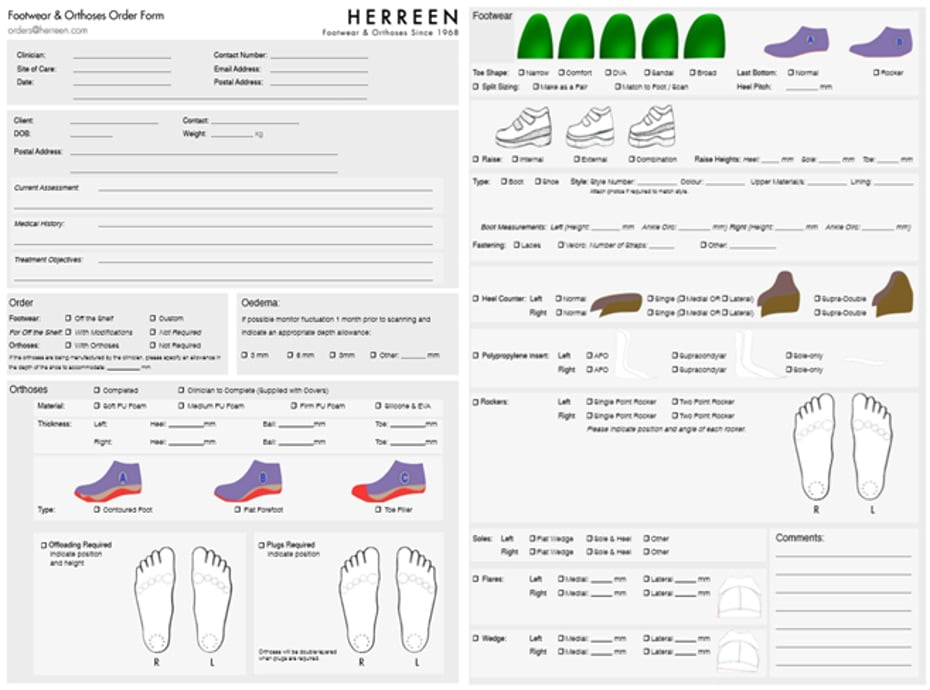

Step #4

Our simple 2-page order form confirms style, colour, lacing, heel counter stiffening and soling requirements.

Step #5

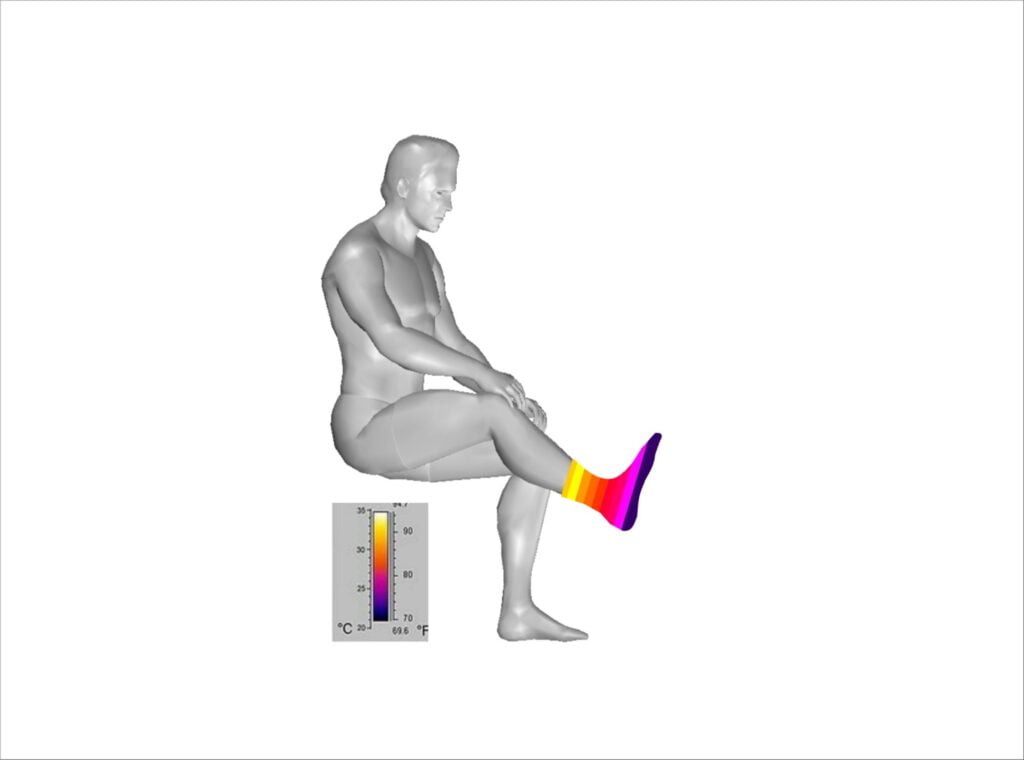

With diabetic patients we have started to take thermal temperature checks.

Step #6

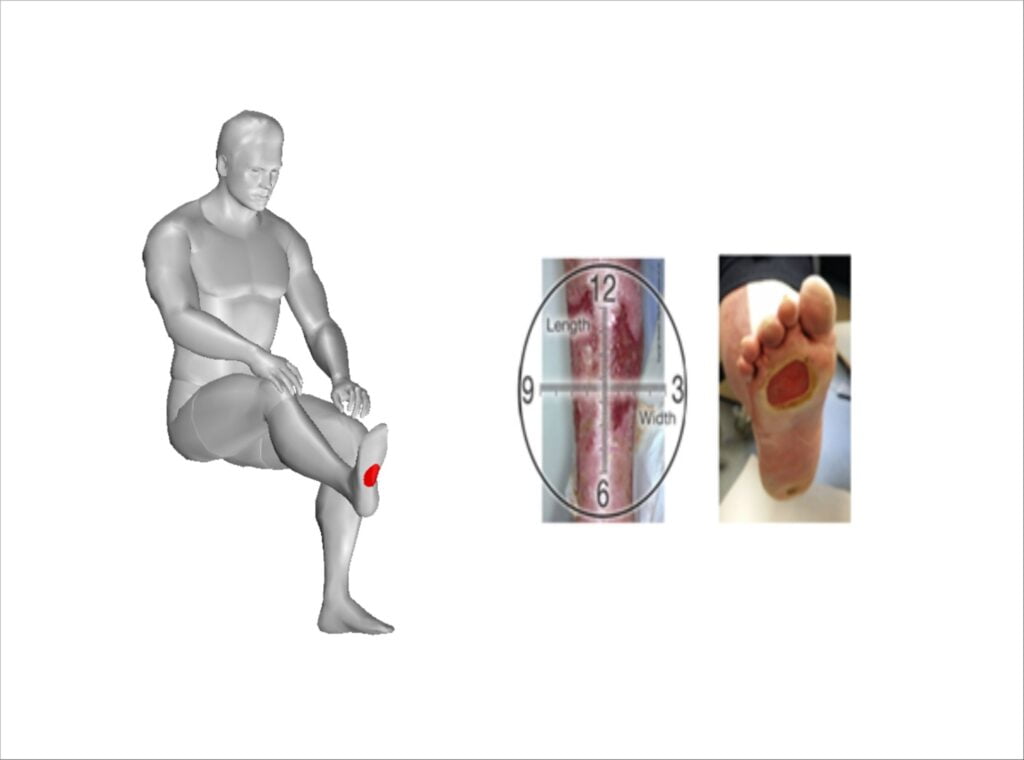

Photos are as good as a thousand words, so any ulcer hot spots or other foot/leg deformities are captured with photos or video.

The design process with cadAdjust

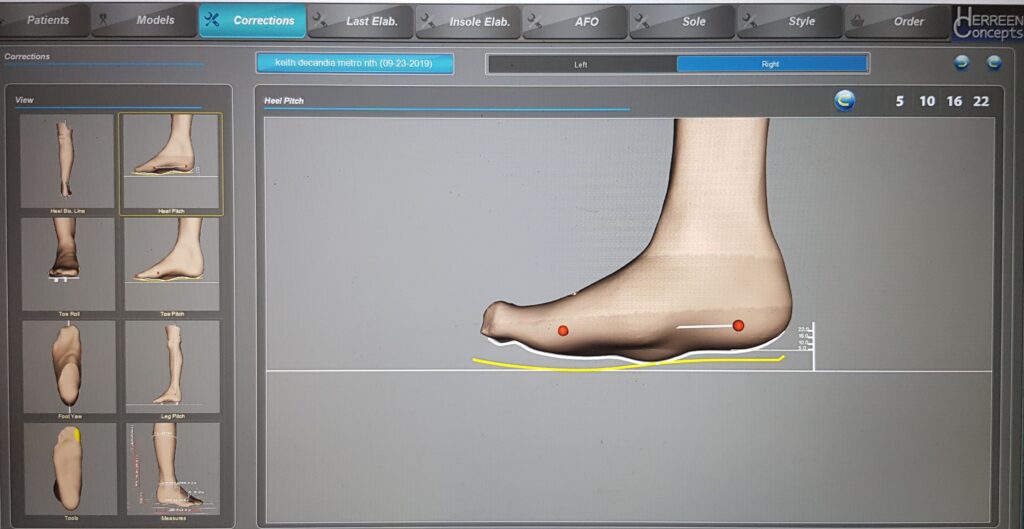

Correct the scan

Once the order form data and scans are done, we use our cadAdjust CAD software to align the foot and ankle and confirm measurements.

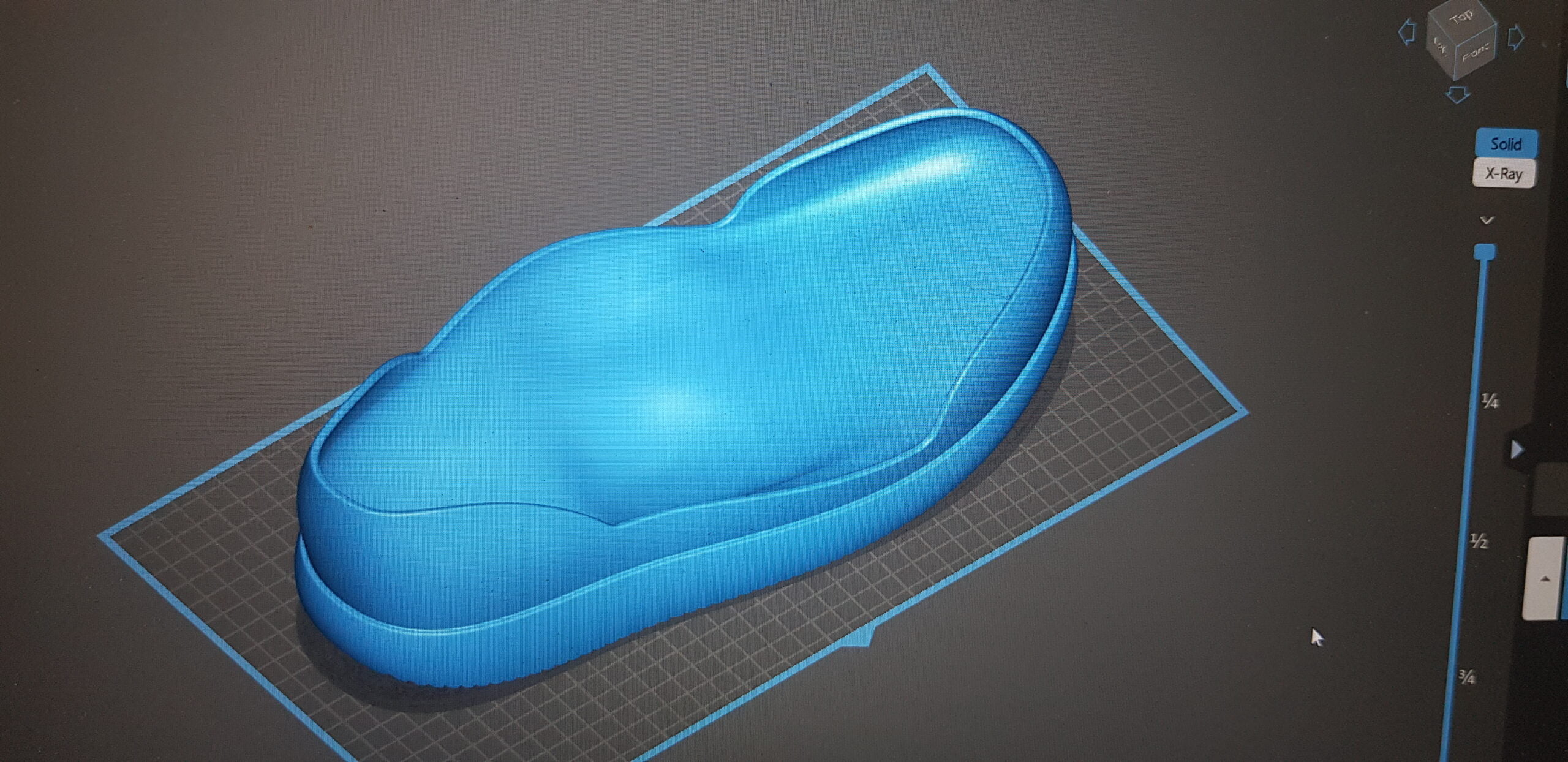

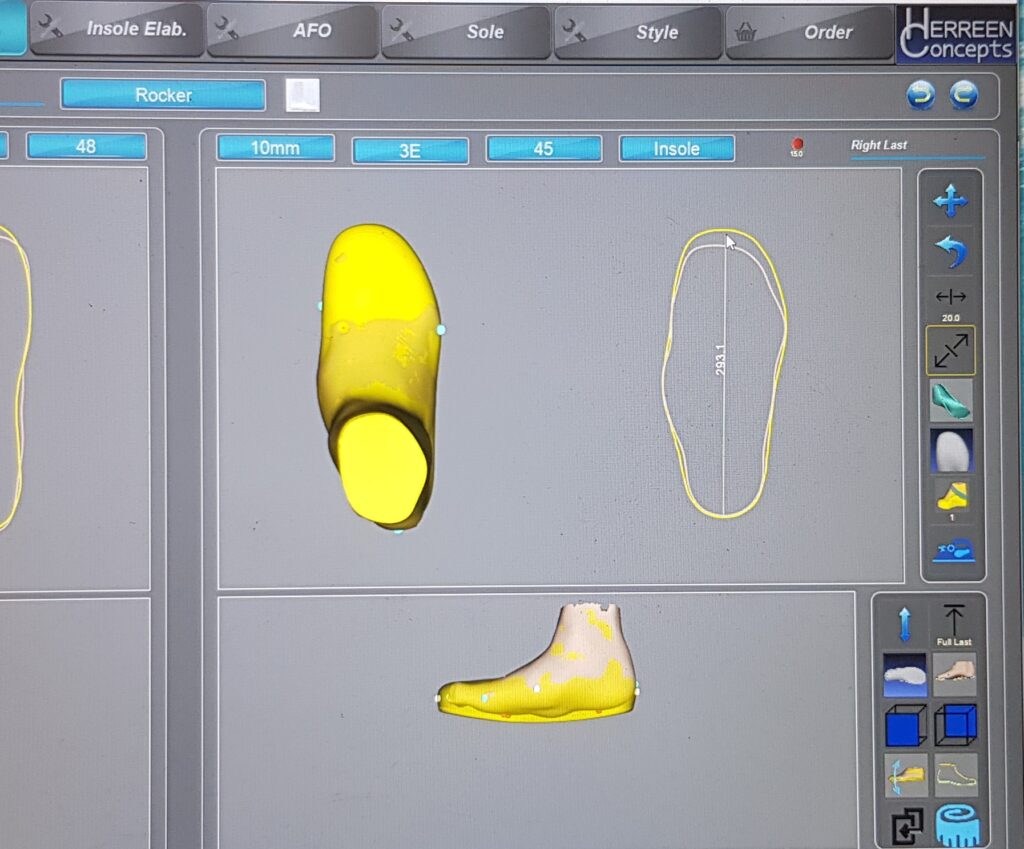

Design Shoe LAST

We add the required toe length and height to the toe box, width and depth of the shoe Last to suit the foot. Toe shape and heel height are also decided at this time.

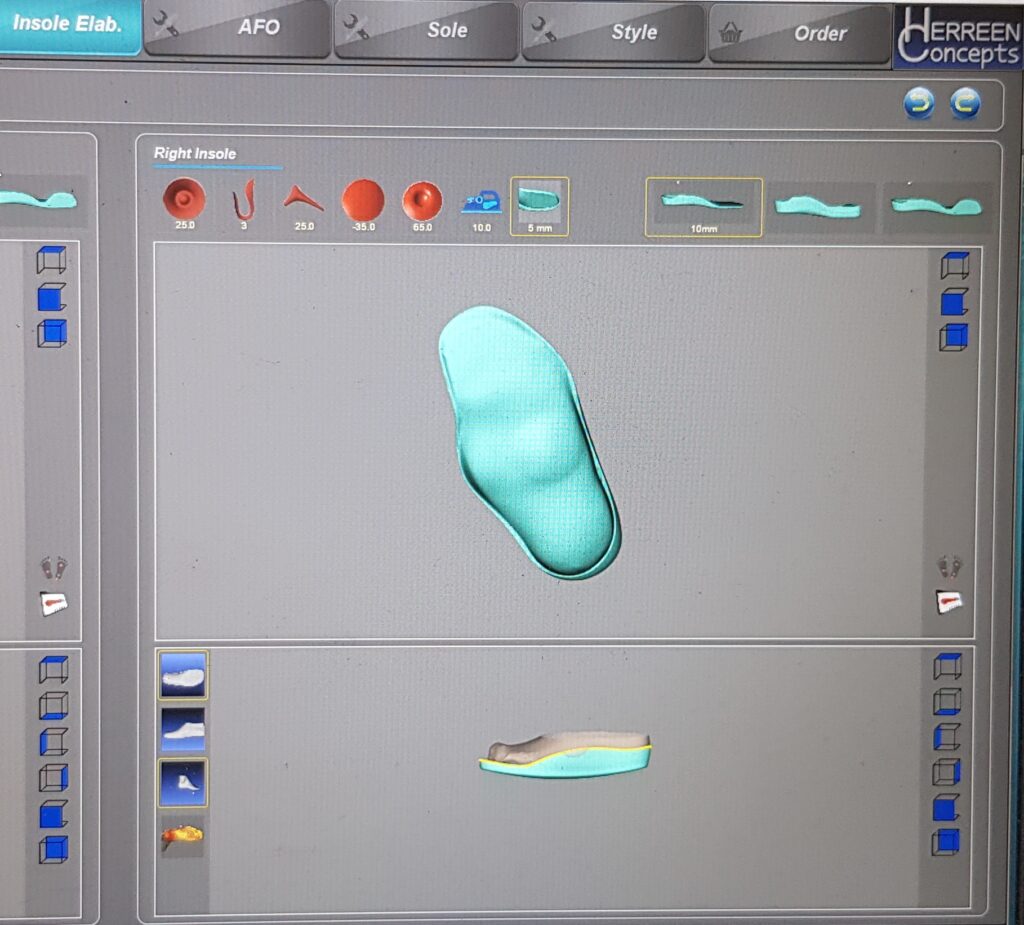

Design Orthotic

Orthotic offloading and thickness are built into the design, any leg length adjustments are also added at this time.

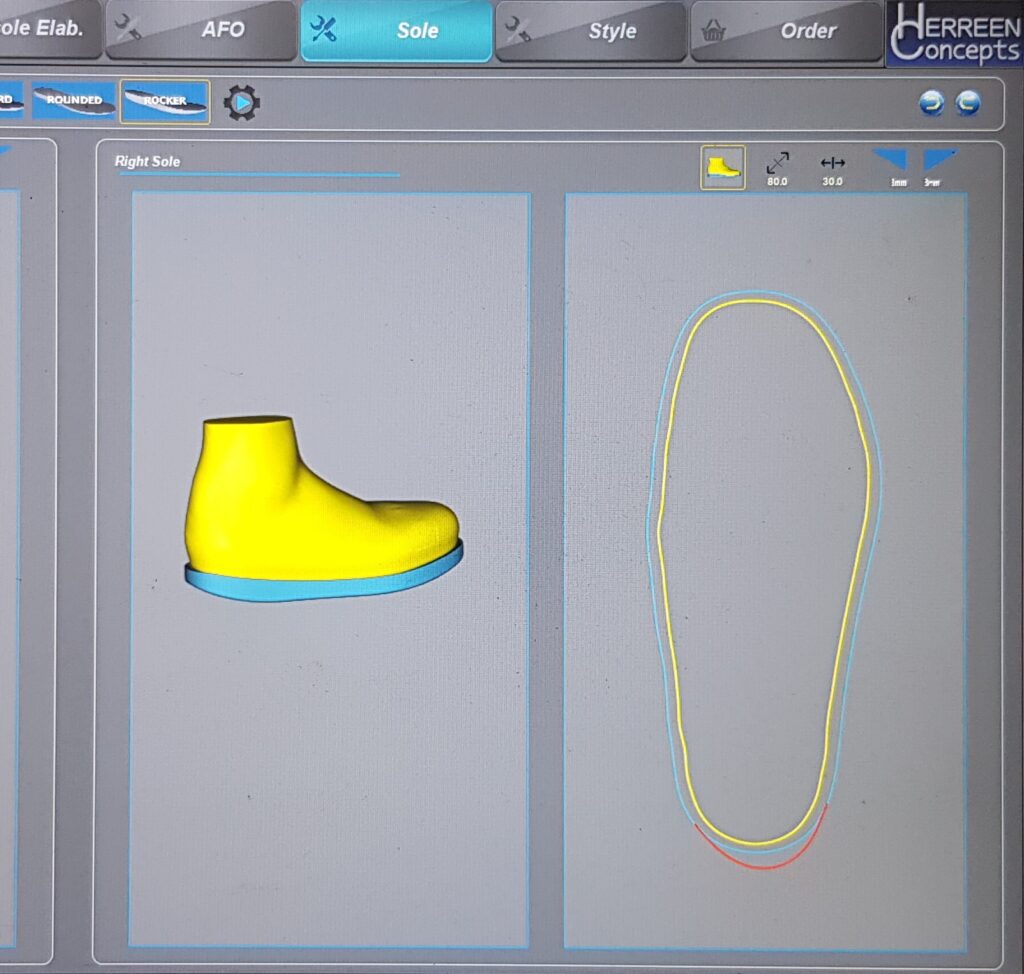

Design Midsoles

We can add medial/lateral flares and raises, leg length sole adjustments and rockers soles all in our SOLE page of cadAdjust – removing 90% of the manual grinding and machine work.

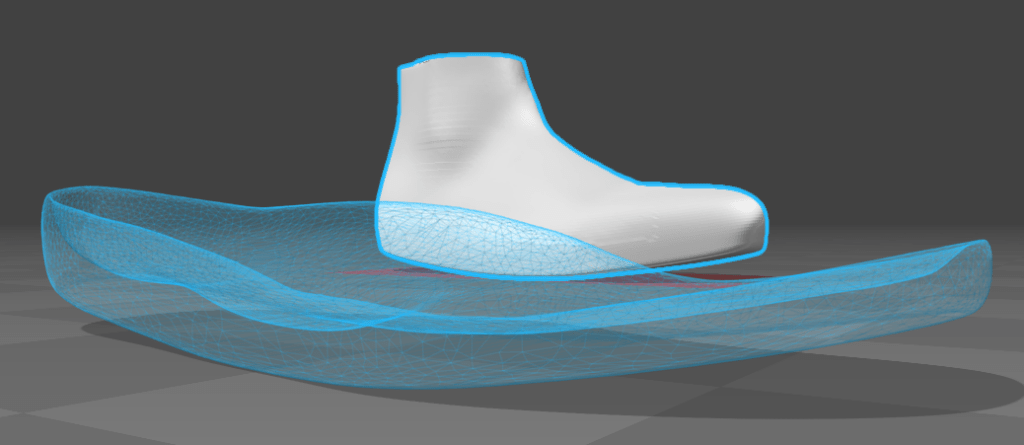

Finished CAD Files

Once the design stages are complete its time to CNC mill or 3D print the parts.

From LASTS to Uppers

We can create the full product in 3D format ready for future concepts.